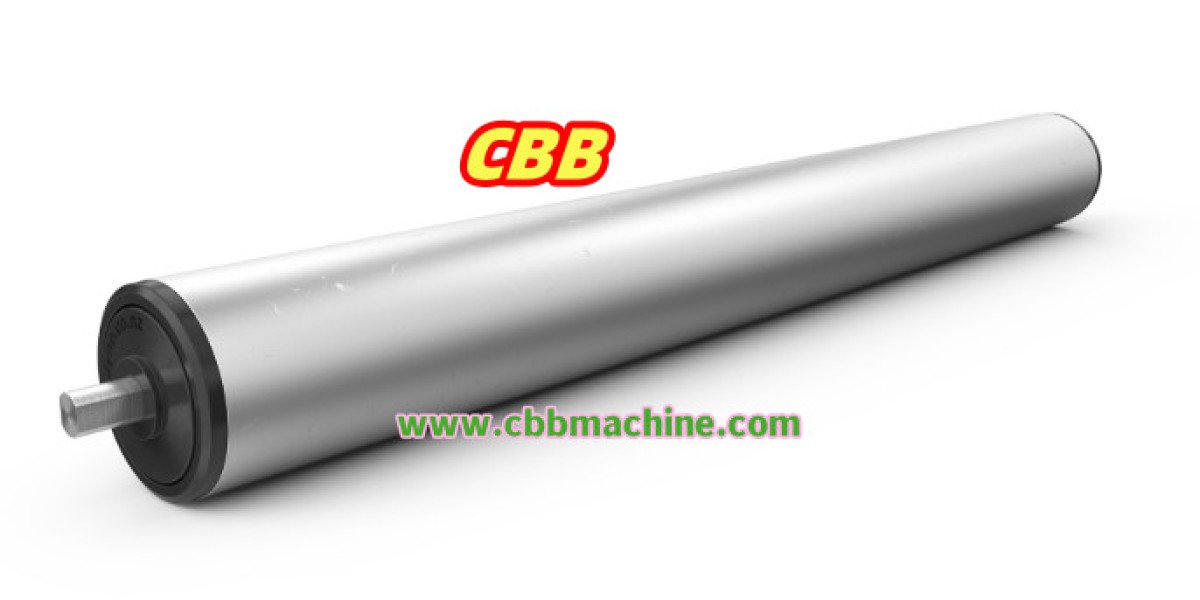

In the world of industrial machinery, the Aluminum Roller has become a widely recognized component, and Cbbmachine has steadily built its presence around this essential tool. The demand for efficiency and smooth operation across multiple industries calls for equipment that blends durability with adaptability, and that is exactly where this technology finds its role. With increasing applications in manufacturing processes, it is no surprise that professionals are looking more closely at the ways it supports their goals.

The use of aluminum as a base material provides natural advantages. Its balance of strength and lightness means rollers can operate consistently without adding unnecessary weight to the system. This contributes to reduced wear on connected parts while keeping maintenance manageable. The stable surface also helps minimize friction, creating a smoother path for materials as they move along production lines.

Beyond these functional qualities, the roller demonstrates versatility. From packaging operations to textile production, its adaptability allows it to integrate seamlessly into varied environments. This is especially important for industries that require precise handling of delicate surfaces, where even minor imperfections can affect the outcome. In such scenarios, the controlled design and reliable finish make a noticeable difference.

Attention must also be given to how it interacts with broader systems. A roller is never an isolated piece; it works in concert with belts, conveyors, and processing units. Its consistent performance ensures that the entire sequence runs without interruption. This integrated role is why decision makers increasingly view it as more than just a replaceable part—it is a factor that supports overall efficiency.

Sustainability has also grown in importance. Aluminum, being highly recyclable, offers an advantage to companies seeking to align production with environmental objectives. Choosing such materials is not only a practical decision but also one that reflects broader responsibility. This layer of consideration often influences procurement, as businesses weigh both performance and long-term impact.

The growing conversation around modernization of factories emphasizes how crucial it is to rely on equipment that aligns with evolving needs. A reliable roller contributes to smoother adaptation, allowing operators to focus on innovation rather than interruptions. It becomes a subtle yet powerful contributor to progress, demonstrating how even seemingly simple components can influence broader outcomes.

Each production line has unique demands, but consistency, durability, and adaptability remain shared priorities. These qualities position the roller as a valuable piece of the larger picture. By ensuring smooth transitions, reducing strain, and offering material efficiency, it continues to play an integral role across diverse industries.

If you are curious about how such machinery can quietly reshape your production process, consider visiting https://www.cbbmachine.com/news/industry-news/aluminum-roller-vs-pvc-roller-which-one-is-better.html . Treat it not as a destination but as an opening—where the details you explore may spark unexpected possibilities.