Sourcing from foreign suppliers requires clarity on commercial responsibilities and potential regulatory changes. When buyers work with China Aluminum Alloy Wire Manufacturers it helps to understand how export documentation and classification practices influence shipment timelines and landed cost. This article addresses practical procurement steps to manage regulatory and export related operational risk without relying on specialist legal language.

Begin procurement conversations by clarifying the documentation the supplier will supply at shipment. Accurate product description on invoices and customs paperwork reduces the chance of administrative delay during clearance. Buyers should request that suppliers confirm the list of documents that will accompany a shipment so brokers can prepare in advance and verify classification and origin statements before goods move.

Understanding the assignment of responsibility for transport events prevents ambiguity. When terms state which party handles export clearance and which handles import clearance the handling and timing steps are clearer. Documenting the handover point and specifying inspection rights at the handover milestone simplifies claims management when damage or nonconformance is suspected during transit. Clear responsibilities reduce operational disputes and speed resolution when incidents occur.

Payment and commercial arrangements impact risk allocation. Escrow arrangements or staged payments tied to inspection milestones give both parties a balanced framework for trust. Buyers should consider including acceptance tests and inspection points in payment schedules so that verification happens before final settlement. This approach smooths procurement execution by aligning payment with documented acceptance.

Working with a customs intermediary familiar with coiled metal shipments adds practical value. Such intermediaries often recognize common pitfalls in packing descriptions and can advise on wording that reduces the likelihood of additional inspections. They can also suggest documentation formats that streamline clearance for heavy or oversized coils that do not fit standard parcel handling processes.

Plan for contingency scenarios in the contract. Define remedies for nonconforming goods and for transport related damage. Specify how sampling and testing will be conducted and whether independent verification will be allowed. Clear dispute resolution steps and timelines shorten administrative cycles and help maintain operational schedules when problems arise.

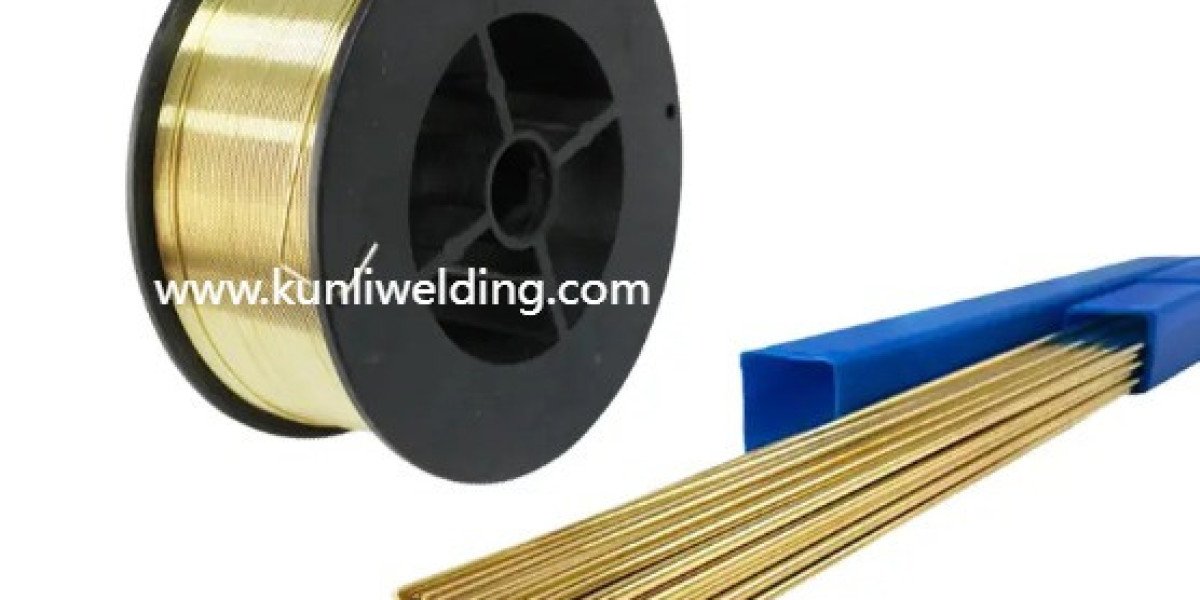

Finally, ensure that packing, labeling, and handling instructions are explicit and that suppliers confirm their packing practices before shipment. Well labeled spools and clear handling guidelines reduce the risk of misrouting and simplify inspection at the receiving site. For orientation on packing options and manufacturer notes about export practice consult manufacturer product pages which often describe available packaging choices and typical documentation. For practical product descriptions and packaging examples see www.kunliwelding.com which many procurement teams use as a starting point when composing export instructions.